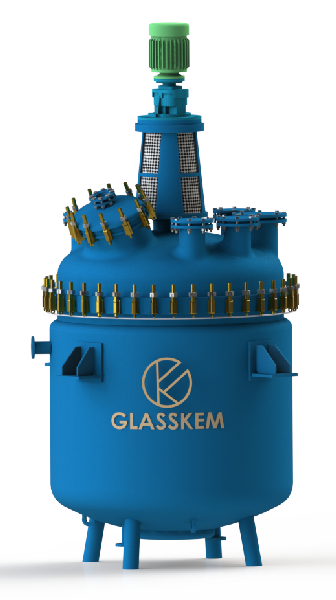

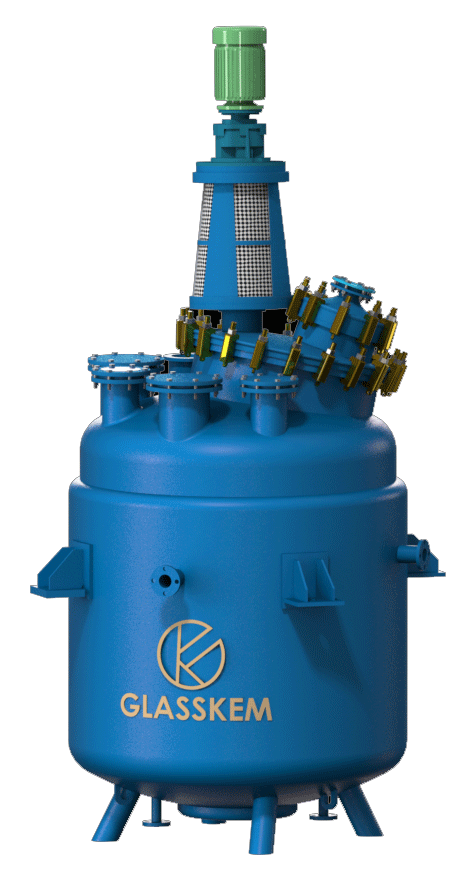

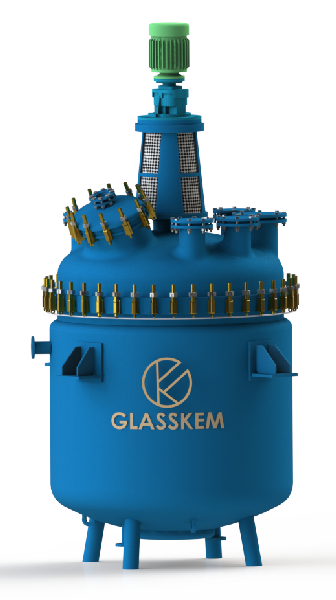

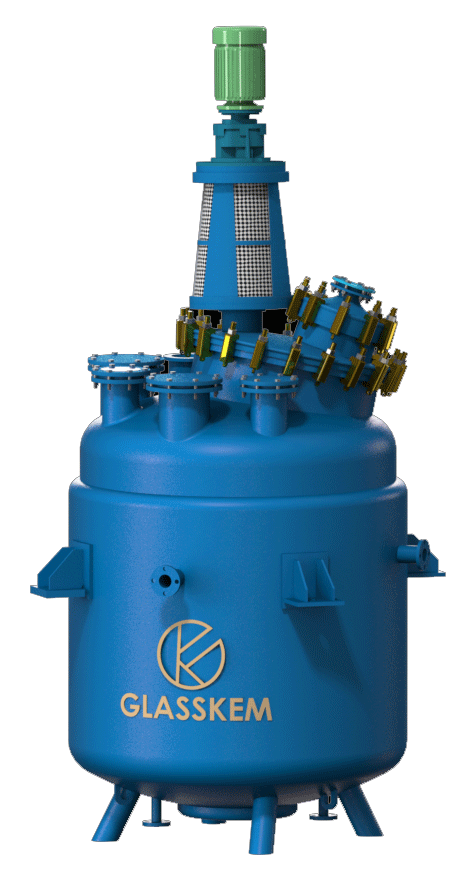

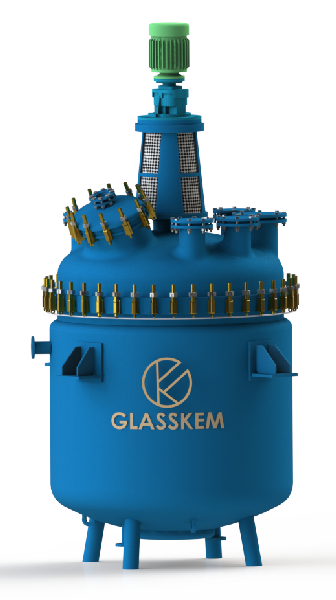

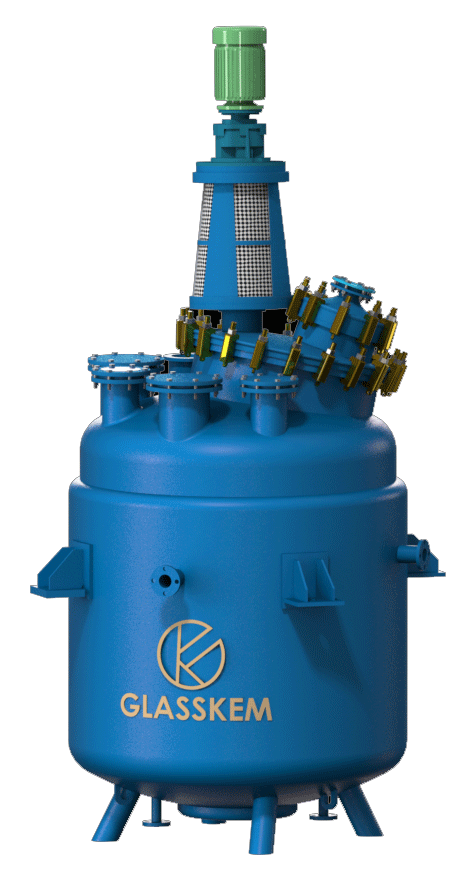

MS GLASS LINED REACTORS

Introducing the MS Glass lined Reactor from Glasskem Equipments – your versatile and reliable solution for various industries.

Features

The MS Glass lined Reactor is a versatile and high-performance solution designed for various industries, including chemical, pharmaceutical, food & beverage, flavor& fragrance, and nutraceutical,pesticides and dyes . This reactor provides reliable and efficient performance with its exceptional corrosion resistance, thermal stability, mechanical strength, and impermeable surface finish.

- Corrosion resistant

- Thermally stable

- Mechanically strong

- Impermeable surface finish

Applications & Benefits

This reactor is well-suited for various applications, including elevated or reduced temperature and pressure chemical reactions and blending (mixing) of non-reacted elements or compounds. By utilizing the MS Glass lined Reactor, users can benefit from the following:

- Increased safety

- Improved efficiency

- Reduced costs

- Extended equipment life

Construction & Specification

Constructed with a glass-lined steel vessel and equipped with an agitator, the MS Glass lined Reactor ensures optimal performance and durability. It features a closed-welded design without a large main opening and is jacketed for efficient heating and cooling. Furthermore, the reactor’s specifications are customizable to meet specific requirements, and it is available in various sizes and configurations.

The MS Glass lined Reactor offers exceptional corrosion resistance, thermal stability, and mechanical strength, making it an ideal choice for various industries. Its versatility and the benefits of increased safety, improved efficiency, reduced costs, and extended equipment life make it a valuable investment. With a glass-lined steel vessel, agitator, and customizable specifications, this reactor provides reliable performance tailored to specific needs.

- Glass-lined steel vessel with agitator

- Closed-welded reactor without a large main opening

- Jacketed for heating and cooling

- Customizable to meet specific requirements

- Available in a variety of sizes and configurations

How to Avoid Damage in Glass-Lined Equipment

- Mechanical damage: Handle equipment carefully, and avoid impacts and excessive pressure.

- Thermal damage: Prevent rapid temperature changes, ensure proper insulation, and adhere to temperature limits.

- Electrical damage: Ensure proper grounding, avoid flammable solvents, and follow voltage limits.

- Chemical damage: Select appropriate glass lining, avoid incompatible chemicals, and flush with clean water afterward.

Why Choose PFG Glasskem Inc.?

Expertise in Glass Lining Technology

Our team of experienced professionals has the expertise to design and manufacture the best glass-lined reactors for our clients.

Exceptional

Quality

Our commitment to quality is reflected in our products, designed to meet the highest industry standards.

Trusted by Industry Leaders

Our clients include industry leaders who trust us to provide the best solutions for their process equipment needs.

Excellent Customer Support

We pride ourselves on providing exceptional customer support, ensuring that our clients get the assistance they need when they need it.